Quality management

Storage management

As a service to our production partners our experienced agronomists take care of the storehouse monitoring and support our farmers during the storage season from October to June. More than 120 storehouses including cold storage and box storage are surveyed, continuously.

The results of this process is the basis to apply our storage management in an optimal way.

Tailor-made ventilation and temperature control systems are programmed for each individual stored lot. Project co-operations with various scientific facilities aim at continuously improvement of our storage management.

Technical innovations are driven by Fangmeier in co-operation with the leading manufacturers in potato technology.

Processing

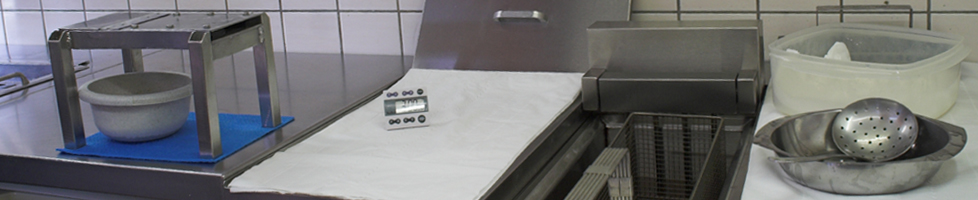

Fangmeier Agrarhandel supplies washed or unwashed, opti-sorted and handpicked lots to its customers. Decades of experience and due diligence enable Fangmeier to process fresh and stored crisp potatoes in a quality conserving way.

Qualified employees with longtime experience check the loads and protect our customers from foreign objects and undesirable quality in consignments. A high degree of technical reliance enables the demanded just-in-time logistics.

Regular trainings support our staff to achieve best results in processing the crisp potatoes complying to our customers’ requirements.

Quality monitoring

Both fresh and stored volumes undergo a close monitoring and sampling. The lab at our main facility in Dueversbruch allows us to customer-specifically select lots complying to a multitude of individual quality paramenters.

After quality monitoring each warehouse is sampled in short intervals for sugar and acrylamide development. Reconditioning is applied as necessary. Thereby we assure conserving the adequate quality for each customer.

An accredited lab samples the lots for pesticide and heavy metal residues. Apart from this we maintain a close co-operation with the local and national Plant Protection Service regarding the long-term quality assurance.